ABL laminate tubes

Provide protection against light, air and moisture. Perfect for toothpastes and pharmaceutical products.

PBL laminate tubes

Maintain form, shape and look. Perfect for beauty and cosmetic products.

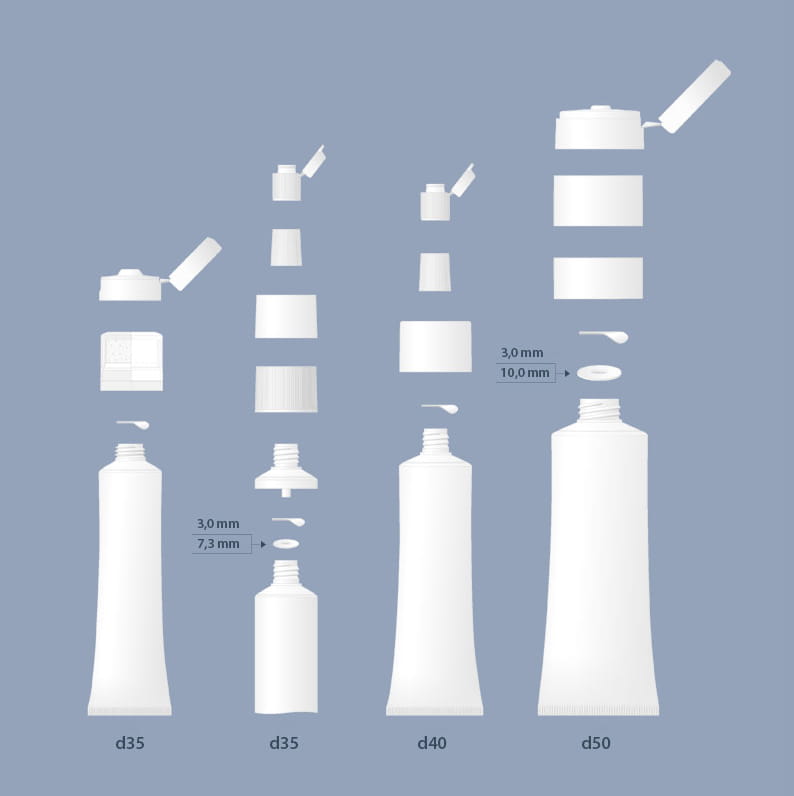

Shoulders

Countless options. Option to use shoulders made from recycled plastic materials.

Caps

Various designs. Option to use caps made from recycled plastic materials.

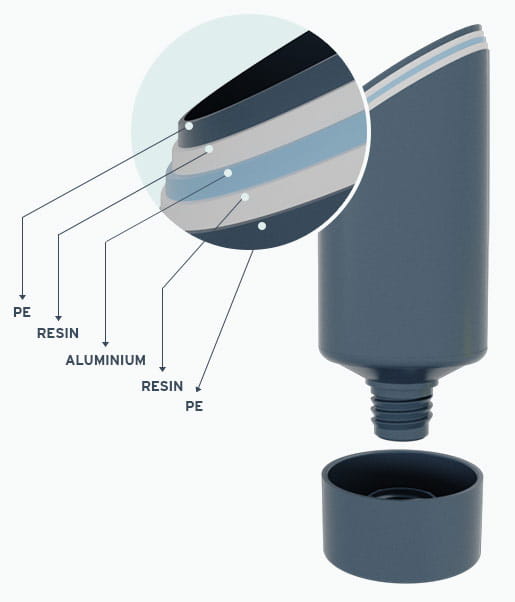

What is an ABL tube?

ABL tubes comprise 3 types of layers – polyethylene, copolymer and aluminum foil. The aluminum barrier layer protects against light, air, moisture and absorption of flavors from the packaging or the environment.

They are most commonly used for toothpaste products, but also find application for creams, gels, ointments and pastes. They are distinguished by their ability to hold their shape after squeezing.

- cosmetics

- pharmaceutical

- food industry

- household and industrial chemicals

- Colored printing up to 6 colors + protective varnish

- Glossy/matte finish

- Hot or cold stamping – gold, silver, color

- Top sealing membrane

- Shrink sleeve

- ABL foil can be white, gray or with holographic effect

- The tubes are packed in plastic or carton boxes. Filled boxes are stacked on Euro pallets (if necessary) with dimensions 800 x 1200 mm and each pallet is wrapped with PE stretch film.

Order request information

Tube diameter

Tube length (volume)

Shoulder type

Cap type and color

Design

Quantity

ABL Size table